Mechanical Music Movement Troubleshooting for Beginners in 2025

Mechanical Music Movement repairs often start with patience and careful observation. Many people find that understanding the mechanism, motorized music box core, and common issues leads to successful fixes. Wholesale Music Movement Suppliers, OEM Music Box Core Manufacturers, and Bulk Order Music Movement Solutions offer valuable resources for those seeking quality parts.

Key Takeaways

- Always prioritize safety by preparing a clean, well-lit workspace, wearing protective gear, and following the instruction manual before starting any repair.

- Use the right tools like precision screwdrivers, tweezers, and a soft brush to carefully clean, inspect, and adjust the music movement parts for smooth operation.

- Diagnose common issues by checking the winding key, comb, cylinder, and spring; clean dust regularly; and seek professional help for complex repairs or broken parts.

Mechanical Music Movement Safety Basics

Essential Safety Tips for Beginners

Safety remains the top priority when working with any Mechanical Music Movement. Beginners should always keep their workspace clean and free from clutter. Sharp tools and small parts can cause injuries if left unattended. Wearing safety glasses protects the eyes from flying debris. Gloves help prevent cuts and keep hands clean.

A well-lit area allows for better visibility of tiny components. Beginners should avoid distractions, such as loud music or mobile phones, during repairs. They should also keep food and drinks away from the workspace to prevent spills.

Tip: Always read the instruction manual before starting any repair. Manuals often include important safety information specific to each model.

Precautions Before Handling Mechanical Music Movement

Before touching any part of a Mechanical Music Movement, beginners should wash their hands to avoid transferring oils or dirt. They should disconnect any power sources if the device uses electricity. Using a soft cloth or mat under the mechanism prevents scratches and damage to delicate parts.

Organizing tools and parts in small containers helps prevent loss. Beginners should check for loose clothing or jewelry that might get caught in moving parts. They should never force any component, as this can cause permanent damage.

A checklist can help beginners remember each step:

- Wash hands and prepare workspace

- Wear safety gear

- Remove distractions

- Organize tools and parts

- Read the manual

Following these steps ensures a safer and more successful repair experience.

Mechanical Music Movement Tools and Workspace Setup

Must-Have Tools for Mechanical Music Movement Repair

Every beginner needs the right tools to repair a Mechanical Music Movement. These tools help with careful adjustments and prevent damage to small parts. A basic toolkit should include:

- Precision screwdrivers: These fit tiny screws without slipping.

- Tweezers: They help pick up and place small components.

- Needle-nose pliers: These grip and bend wires or pins.

- Soft brush: This removes dust from delicate surfaces.

- Cleaning cloth: It keeps parts free from fingerprints and debris.

- Magnifying glass: This tool helps spot tiny defects or misalignments.

- Lubricant: Use a light, non-gumming oil for moving parts.

Tip: Store all tools in a dedicated box to avoid losing them.

Organizing a Safe and Efficient Workspace

A well-organized workspace makes repairs easier and safer. Choose a flat, stable table with good lighting. Place a soft mat or towel on the surface to protect the Mechanical Music Movement from scratches. Keep all tools within easy reach. Use small containers or trays to separate screws and parts.

Remove any unnecessary items from the area. This reduces the risk of losing important pieces. Label containers for different parts to stay organized. Always clean the workspace before and after each repair session.

A tidy and well-lit area helps prevent mistakes and keeps the repair process smooth.

Understanding the Mechanical Music Movement Mechanism

Key Parts of a Mechanical Music Movement

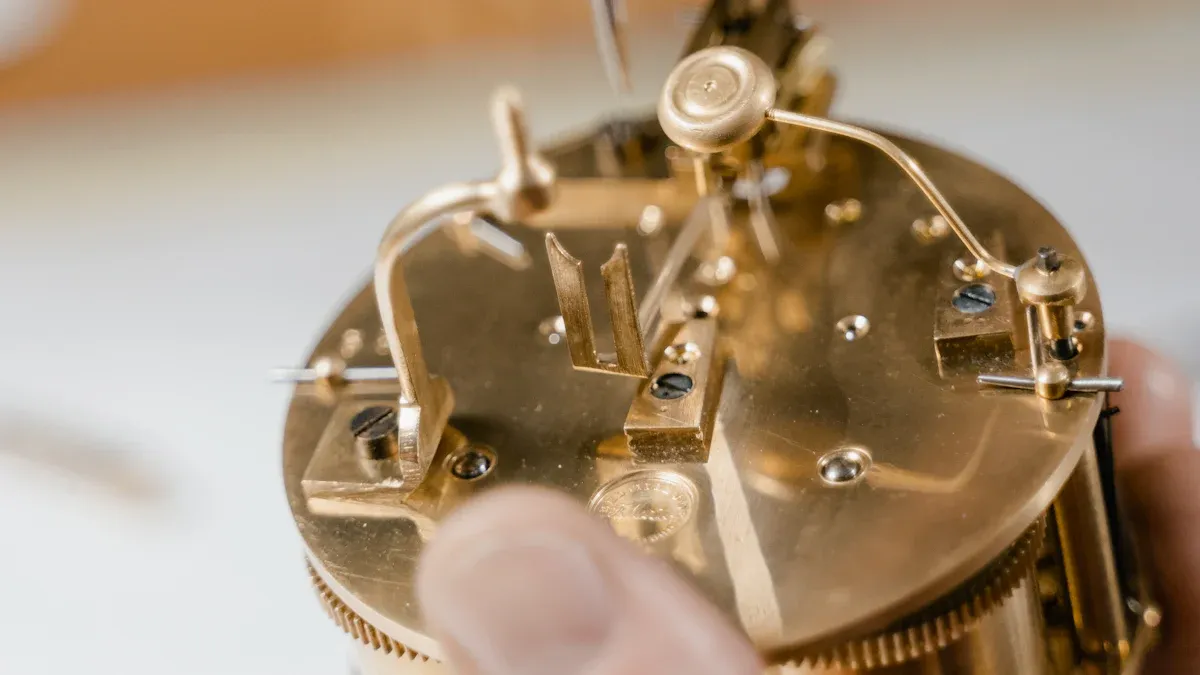

A Mechanical Music Movement contains several important parts. The main components include the cylinder or disc, the comb, the spring-driven motor, and the governor. The cylinder or disc holds small pins or bumps. These pins pluck the teeth of the comb to create musical notes. The comb consists of metal teeth of different lengths. Each tooth produces a specific pitch when struck.

The spring-driven motor stores energy. When someone winds the key, the spring tightens and holds potential energy. The governor controls the speed of the mechanism. It uses a fan or flywheel to keep the tempo steady. Some movements also include gears and levers. These parts help transfer energy and control the timing of the notes.

Note: Each part must stay clean and undamaged for the music box to work well.

How Mechanical Music Movement Components Work Together

The process begins when a person winds the key. The spring-driven motor releases energy slowly. This energy turns the cylinder or disc. As it rotates, the pins on the cylinder pluck the comb’s teeth. Each pin lines up with a specific tooth to play the correct note. The governor keeps the speed even, so the melody sounds smooth.

Gears and levers help move the parts in sync. They ensure the notes play in the right order. All these components must work together for the Mechanical Music Movement to produce clear and pleasant music.

Identifying Common Mechanical Music Movement Problems

No Sound or Music from the Mechanism

When a music box produces no sound, several issues may cause the silence. The most common reasons include a disengaged comb, a broken spring, or a misaligned cylinder. Sometimes, dust or debris blocks the pins from striking the comb.

To troubleshoot this issue, follow these steps:

- Check if the winding key turns smoothly.

- Inspect the comb for any visible damage or misalignment.

- Look for obstructions on the cylinder or disc.

- Ensure the spring is not broken or fully unwound.

Tip: Use a magnifying glass to examine small parts closely. Even a tiny piece of lint can prevent the mechanism from playing music.

If the problem persists after these checks, the mechanism may require professional attention.

Stuck or Jammed Mechanical Music Movement

A stuck or jammed mechanism often results from foreign objects, bent pins, or worn gears. When the movement refuses to turn or makes grinding noises, immediate action prevents further damage.

Common causes include:

- Dust or debris inside the movement

- Bent or broken pins on the cylinder

- Worn or misaligned gears

A simple cleaning with a soft brush can remove dust. If pins appear bent, use tweezers to straighten them gently. For worn gears, replacement may be necessary.

Alert: Never force the winding key. Forcing can break the spring or damage internal parts.

Off-Key or Distorted Notes in Mechanical Music Movement

Distorted or off-key notes usually indicate problems with the comb or cylinder. A bent tooth on the comb or a misaligned pin can change the pitch or create buzzing sounds.

To identify the source:

- Listen for which notes sound wrong.

- Inspect the comb for bent or missing teeth.

- Check the cylinder for misplaced or damaged pins.

| Problem | Possible Cause | Solution |

|---|---|---|

| Buzzing or rattling | Loose comb screws | Tighten screws |

| Flat or sharp notes | Bent comb teeth | Gently straighten teeth |

| Missing notes | Broken or missing pins | Replace pins if possible |

Note: Handle the comb with care. Metal teeth can break if bent too far.

Winding and Overwinding Issues

Winding problems often occur when users apply too much force or wind the key in the wrong direction. Overwinding can cause the spring to snap or become stuck.

Signs of winding issues include:

- The key will not turn.

- The mechanism does not play after winding.

- The spring feels loose or unresponsive.

To address these issues:

- Stop winding immediately if resistance increases.

- Allow the spring to unwind naturally if possible.

- If the spring remains stuck, consult a specialist.

Tip: Always wind the key slowly and stop when resistance is felt. This practice extends the life of the spring and prevents damage.

Step-by-Step Mechanical Music Movement Troubleshooting

Diagnosing Mechanical Music Movement Issues

Diagnosing problems in a music box requires careful observation. First, listen to the sound and watch the movement. If the music does not play, check if the key turns. If the sound is distorted, look at the comb and cylinder. Use a magnifying glass to inspect small parts. Take notes on what you see and hear.

A simple checklist helps beginners diagnose issues:

- Does the key turn smoothly?

- Does the cylinder rotate?

- Are all comb teeth present and straight?

- Is there any visible dust or debris?

- Do any parts look bent or broken?

Tip: Take photos before disassembling the mechanism. Photos help with reassembly.

If you cannot find the problem, consider contacting Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. for expert advice or replacement parts.

Cleaning the Mechanical Music Movement

Dust and dirt often cause problems in music boxes. Cleaning the mechanism restores clear sound and smooth movement. Always use a soft brush to remove dust from the cylinder, comb, and gears. A can of compressed air helps blow away particles from hard-to-reach areas.

Follow these steps for safe cleaning:

- Remove the movement from the case if possible.

- Place the mechanism on a soft, clean cloth.

- Gently brush away dust from all parts.

- Use tweezers to pick out lint or hair.

- Wipe metal surfaces with a dry, lint-free cloth.

| Tool | Use |

|---|---|

| Soft brush | Removes dust from surfaces |

| Tweezers | Picks up small debris |

| Compressed air | Blows away fine particles |

| Lint-free cloth | Wipes metal parts clean |

Alert: Never use water or harsh chemicals. Moisture can rust metal parts and damage the mechanism.

Lubricating Mechanical Music Movement Parts

Lubrication keeps the music box running smoothly. Use a light, non-gumming oil made for small machines. Apply a tiny drop to the gears and moving joints. Avoid over-oiling, as excess oil attracts dust.

Steps for proper lubrication:

- Identify moving parts such as gears and axles.

- Use a needle oiler or toothpick to apply a small drop of oil.

- Wipe away any extra oil with a clean cloth.

- Turn the key gently to spread the oil.

Note: Lubricate only the metal parts that move. Do not oil the comb or cylinder pins.

Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. recommends lubricating the mechanism once a year for best performance.

Making Minor Adjustments to the Mechanism

Sometimes, small adjustments fix common problems. If a comb tooth bends, use tweezers to straighten it gently. If a pin on the cylinder moves out of place, press it back with a small tool. Tighten any loose screws with a precision screwdriver.

Common minor adjustments include:

- Straightening bent comb teeth

- Adjusting cylinder pins

- Tightening loose screws

- Aligning gears

Tip: Work slowly and check your progress after each adjustment. Rushing can cause more damage.

If the problem continues after these steps, seek help from a professional or contact Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. for support.

When to Seek Professional Mechanical Music Movement Help

Signs a Repair Is Too Complex for Beginners

Some repairs require more skill and experience than a beginner has. If a music box has broken or missing gears, a cracked comb, or a damaged spring, a beginner should not try to fix it. These parts need special tools and knowledge. If the mechanism makes loud grinding noises or if parts fall out, the problem may be serious. When a repair involves soldering or replacing tiny pins, a specialist should handle the job.

Alert: If a music box has sentimental or high monetary value, a beginner should avoid risky repairs. Mistakes can cause permanent damage.

A beginner should also stop if they feel unsure or confused during the repair. Safety comes first.

How to Find a Qualified Mechanical Music Movement Specialist

Finding the right specialist helps protect the music box. Start by searching for local clock or music box repair shops. Many jewelers also know how to fix music boxes. Ask for recommendations from friends or online forums. Look for reviews and check if the specialist has experience with similar repairs.

A good specialist will answer questions and explain the repair process. They should provide a clear estimate of the cost and time needed. Use this table to help choose a specialist:

| Criteria | What to Look For |

|---|---|

| Experience | Years working with music boxes |

| Reviews | Positive feedback from clients |

| Communication | Clear answers and estimates |

Tip: Always ask about warranties or guarantees on repair work.

- Beginners should follow each troubleshooting step with care.

- Safe repair techniques protect both the user and the mechanism.

- Most basic repairs remain within reach for those who stay patient.

Remember: Consistent practice and attention to detail lead to successful Mechanical Music Movement repairs.

FAQ

How often should someone clean a mechanical music movement?

Experts recommend cleaning the mechanism once a year. Regular cleaning prevents dust buildup and keeps the music box working smoothly.

Can a beginner fix a broken spring in a music box?

A broken spring requires special tools and skills. Beginners should contact a professional for spring repairs to avoid further damage.

What type of oil works best for lubricating music box parts?

Use a light, non-gumming oil designed for small machines. Avoid household oils, as they can attract dust and cause sticky residue.