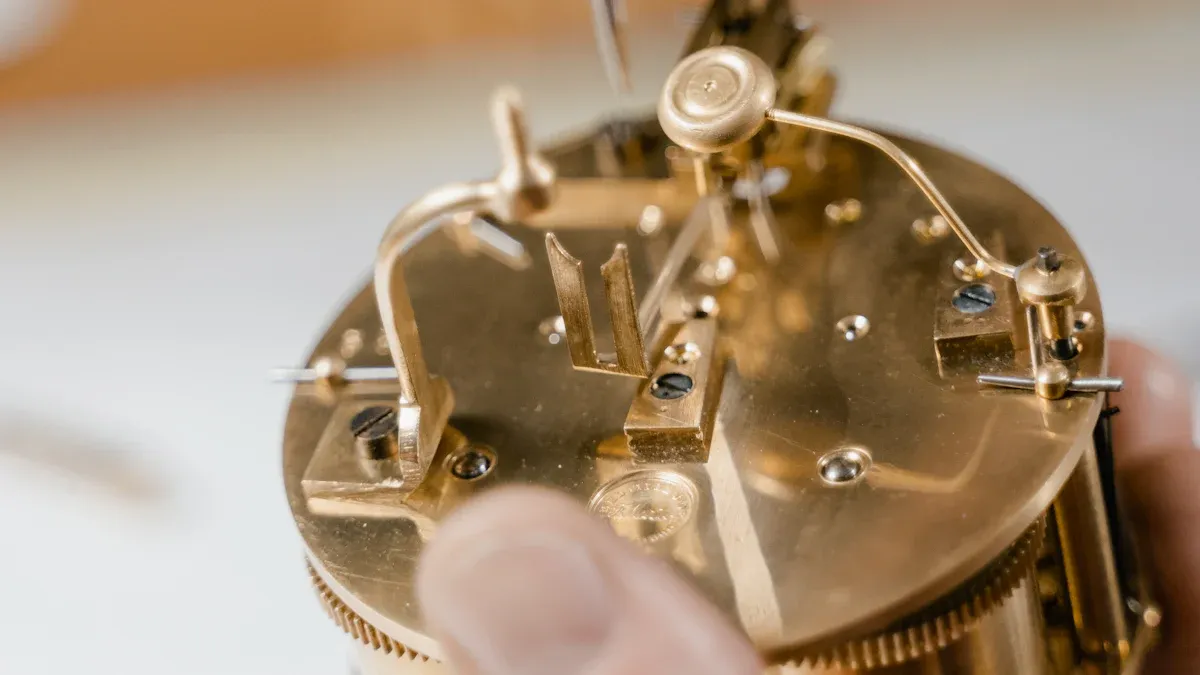

Automating Quality Control in Music Box Mechanism Manufacturing

Automation has revolutionized the way manufacturers ensure quality in music box mechanisms. Recent advancements highlight its ability to enhance precision and reduce human error through innovative techniques:

- 3D printing creates intricate shapes with unmatched accuracy, vital for the delicate components of a music box mechanism.

- Redesigned structures improve performance across critical parts like the pinned cylinder and comb.

- Material choices, such as PLA and metal spacers, significantly boost sound quality in custom music boxes.

These innovations make manufacturing more efficient, ensuring consistent quality in mechanical music boxes and music box movements for crafts.

Key Takeaways

- Automation makes music box making more accurate. It lowers mistakes and ensures all parts meet high standards.

- Using machine vision helps find defects easily. This checks tiny parts to keep quality and performance steady.

- Automation saves time and money. Faster checks and less waste mean big savings and more profit.

Challenges in Quality Control for Music Box Mechanisms

Limitations of Manual Inspections

Human error in detecting defects in intricate music box mechanisms

Manual inspections often struggle to identify defects in the delicate components of a music box mechanism. The intricate design of parts like the pinned cylinder and comb requires a level of precision that human eyes cannot consistently achieve. Even minor imperfections can disrupt the acoustic performance, leading to subpar sound quality. This reliance on manual methods increases the likelihood of errors, especially when inspecting large volumes of mechanisms.

Inconsistent quality due to subjective manual inspections

Subjectivity in manual inspections creates inconsistencies in product quality. Different inspectors may apply varying standards, resulting in uneven evaluations. This inconsistency poses challenges for manufacturers aiming to meet stringent international safety and quality standards. Smaller manufacturers, in particular, face barriers due to the high costs associated with rigorous testing and compliance.

Impact on Manufacturing Outcomes

Higher production costs from inefficiencies

Inefficiencies in manual quality control processes contribute to higher production costs. Repeated inspections and rework cycles consume valuable time and resources. These inefficiencies can strain budgets, especially for manufacturers producing intricate music box mechanisms at scale.

Delays in identifying and addressing defects, affecting product reliability

Manual inspections often fail to detect defects early in the production cycle. Delayed identification of issues can compromise the reliability of the final product. Customers expect consistent quality, and delays in addressing defects can harm brand reputation and customer trust.

Note: Addressing these challenges requires adopting automated solutions that enhance precision, reduce costs, and ensure consistent quality across all music box mechanisms.

Benefits of Automating Quality Control in Music Box Mechanism Manufacturing

Enhanced Precision and Accuracy

Automated systems detect micro-defects and ensure component tolerances meet strict standards

Automation introduces advanced systems capable of identifying micro-defects that manual inspections often overlook. These systems ensure that every component of a music box mechanism adheres to strict tolerances, maintaining the intricate balance required for optimal performance. By detecting flaws early, manufacturers can prevent defective parts from progressing through the production line, safeguarding the quality of the final product.

Machine vision technology inspects intricate mechanisms with unmatched precision

Machine vision technology revolutionizes the inspection process by utilizing high-resolution cameras and AI-powered image analysis. This technology excels at examining the intricate components of a music box mechanism, such as the pinned cylinder and comb, with unparalleled precision. Unlike human inspectors, machine vision systems maintain consistent accuracy, ensuring that even the smallest imperfections are identified and addressed promptly.

Improved Efficiency and Cost Savings

Faster inspection processes reduce production time

Automated quality control significantly accelerates inspection processes. Machines can evaluate multiple components simultaneously, reducing the time required for thorough inspections. This efficiency allows manufacturers to increase production rates without compromising quality, meeting market demands more effectively.

Automation minimizes waste and lowers labor costs, enhancing profitability

By reducing human error, automation minimizes material waste and rework. It also lowers labor costs by streamlining repetitive tasks, enabling workers to focus on more complex responsibilities. According to industry data, automation can reduce overall production costs by 30-50% and logistics costs by up to 45%. These savings directly enhance profitability, making automation a valuable investment for manufacturers.

| Benefit | Metric/Percentage |

|---|---|

| Cost Reduction | 15-25% in supply chain management |

| 30-50% overall | |

| 10-40% in maintenance costs | |

| 15-20% HR labor time savings | |

| Logistics costs | Up to 45% reduction |

| Customer service costs | 30-60% decrease |

| Accuracy Improvement | 60% fewer human errors |

| Quality control accuracy | 94.5-96% defect prediction accuracy |

| AI inspection accuracy | 99.9% compared to 80-90% for humans |

Consistent Product Quality

Ensures every music box mechanism meets high-quality standards, improving customer satisfaction and brand reputation

Automation ensures that every music box mechanism meets the same high-quality standards. Consistency in quality enhances customer satisfaction, as buyers receive reliable products that perform as expected. This reliability strengthens brand reputation, positioning manufacturers like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. as leaders in the industry. By delivering superior products, companies can build long-term customer loyalty and gain a competitive edge in the market.

Key Technologies Driving Automation in Music Box Mechanism Manufacturing

Machine Vision Systems

High-resolution cameras and AI-powered image analysis for defect detection

Machine vision systems play a pivotal role in automating quality control for music box mechanisms. These systems use high-resolution cameras to capture detailed images of components. Advanced AI-powered image analysis then processes these images to detect defects that might escape human observation. This technology identifies micro-level imperfections, such as misaligned pins or irregular comb teeth, ensuring that every part meets strict quality standards. By integrating machine vision, manufacturers can achieve unparalleled accuracy in defect detection.

Facilitates inspection of intricate components to ensure functionality

The intricate design of a music box mechanism demands precise inspection to ensure functionality. Machine vision systems excel in this area by analyzing complex components like the pinned cylinder and comb with exceptional precision. These systems evaluate dimensions, alignment, and surface quality, ensuring that each part functions harmoniously. This level of scrutiny guarantees that the final product delivers the desired sound quality and mechanical performance, enhancing customer satisfaction.

IoT and Sensor Integration

Real-time monitoring of mechanical components for early defect detection

The Internet of Things (IoT) and sensor integration enable real-time monitoring of mechanical components during production. Sensors embedded in the manufacturing equipment collect data on parameters such as vibration, temperature, and alignment. This data helps identify potential defects early in the process, preventing faulty components from advancing through the production line. By addressing issues promptly, manufacturers can reduce waste and maintain the reliability of their music box mechanisms.

Data collection and analysis to optimize manufacturing processes

IoT systems not only detect defects but also collect valuable data throughout the production cycle. This data provides insights into equipment performance, material usage, and process efficiency. Manufacturers can analyze this information to identify trends, optimize workflows, and improve overall productivity. For example, data analysis might reveal patterns in defect occurrence, allowing companies to adjust their processes to minimize errors. This proactive approach enhances both quality and efficiency.

Robotics in Assembly and Inspection

Robotic arms for precise handling and assembly of delicate music box mechanisms

Robotic arms have transformed the assembly process for music box mechanisms. These robots handle delicate components with precision, ensuring accurate placement and alignment. Their ability to perform repetitive tasks with consistent accuracy reduces the risk of damage to fragile parts. For instance, robotic arms can assemble the pinned cylinder and comb with exact tolerances, maintaining the intricate balance required for optimal sound production.

Automated inspection processes to maintain consistent quality

In addition to assembly, robotics plays a crucial role in automated inspection. Robots equipped with advanced sensors and cameras can inspect finished products for defects, ensuring consistent quality across all units. These automated inspections eliminate variability and subjectivity, delivering reliable results every time. By integrating robotics into both assembly and inspection, manufacturers can streamline operations and enhance the quality of their music box mechanisms.

Steps to Implement Automation in Music Box Mechanism Manufacturing

Evaluate Current Processes

Identify bottlenecks and inefficiencies in manual quality control

The first step in implementing automation involves a thorough evaluation of existing processes. Manufacturers should identify bottlenecks that slow down production and inefficiencies in manual quality control. For example, repetitive inspections or rework cycles often consume excessive time and resources. By pinpointing these issues, companies can determine where automation will have the greatest impact.

Assess defect rates and areas for improvement

Analyzing defect rates provides valuable insights into the quality of current production methods. Manufacturers should review historical data to identify patterns in defects and areas requiring improvement. This analysis helps prioritize automation efforts, ensuring that critical pain points, such as the inspection of intricate components in a music box mechanism, are addressed first.

Select the Right Automation Tools

Choose technologies tailored to the specific needs of music box mechanism manufacturing

Selecting the right tools is crucial for successful automation. Manufacturers should focus on technologies designed for the unique requirements of music box mechanism production. For instance, machine vision systems and robotic arms are ideal for inspecting and assembling delicate components. Tailored solutions ensure that automation aligns with production goals and enhances overall efficiency.

Ensure scalability and compatibility with existing systems

Automation tools must integrate seamlessly with current manufacturing systems. Scalability is another key consideration, as production demands may increase over time. Choosing flexible technologies allows manufacturers to expand their automation capabilities without significant disruptions. This approach ensures long-term adaptability and cost-effectiveness.

Train Staff and Monitor Performance

Provide comprehensive training for operators and technicians

Training plays a pivotal role in the successful implementation of automation. Operators and technicians must understand how to use and maintain automated systems effectively. Training programs should cover areas such as troubleshooting, system calibration, and data interpretation. A well-trained workforce minimizes downtime and ensures smooth operations.

| Evidence Type | Description |

|---|---|

| Bias in Data | Human interactions can introduce biases in datasets, necessitating careful review. |

| Model Complexity | The black-box nature of deep learning models highlights the need for staff training. |

| Adversarial Attacks | Training prepares staff to mitigate risks like adversarial attacks on models. |

Continuously monitor and optimize automated systems for peak performance

Automation requires ongoing monitoring to maintain peak performance. Regular system evaluations help identify areas for optimization, such as fine-tuning machine vision algorithms or recalibrating robotic arms. Proactive maintenance ensures that automated systems continue to deliver consistent quality and efficiency over time.

Automating quality control transforms music box mechanism manufacturing by ensuring precision, efficiency, and cost-effectiveness.

Companies like Ningbo Yunsheng Musical Movement Manufacturing Co., Ltd. utilize automation to deliver superior product quality, streamline operations, and maximize profitability. Their commitment to innovation positions them as leaders in the industry, setting benchmarks for reliability and customer satisfaction.